This month’s acquisition and rebuild story is from Michael Green in Australia.

Elliot 10M Completed

Photo by Michael Green

“My shaper is an English brand Elliott 10M. I'm told that Elliott shapers are descended from Alba shapers, which are in turn descendants of Royal shapers. Mine dates from around 1965. It was bought on eBay, and from what I've been told, was in a technical college where its main use was to show apprentices what a shaper was. As a result, the bearing surfaces had very little wear, but the machine has suffered from use by students.

Elliot Before

Photo from eBay Ad

Elliot at Arrival

Photo by Michael Green

The above photos show the machine I bid on. After seeing it in reality I must say that the picture did not do it justice. It was much dirtier.

Stub Pin in Ram Head

Photo by Michael Green

Cleaning up was done with kerosene, degreasing fluid, steam cleaning at a local truck detailer's, and the base was even sand blasted.

My shaper came from Townsville in Northern Australia (Queensland) – in the tropics. I live in Adelaide in South Australia, so there was a 1900km (as the crow flies) journey for it to take.

Ram Head & Pin

Photo by Michael Green

Fortunately my company freights things up there sometimes, so I got a good deal to bring it back. As a comparison, that's about the same distance between Tampa Florida and Boston Massachusetts. The third photo shows it just off the truck. The last machine I had trucked was badly damaged, but this trip was uneventful.

Head Pivot Lock

Shaft

Photo by Michael Green

Apart from repainting, there were not many things to fix. One, however, was the pin / stub-shaft by which the tool head is mounted into the ram. I suspect that student usage had distorted it. Getting it out was a hammer and drift job. The bore was checked with a ground spacer and bluing the pin. Inserting it showed a tight spot where the eccentric lock pushed up some material. The raised section was removed with emery cloth.

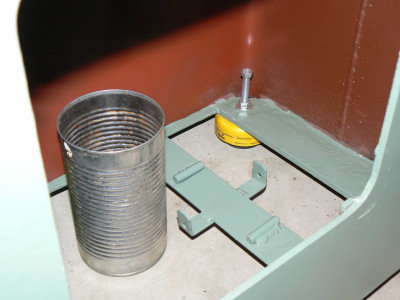

Oil Can &

Bracket

Photo by Michael Green

I always look for areas to improve. There are other areas I want to improve, but while reassembling I marked the pivot lock shaft with some light cuts from a grinder cut off wheel so there was visual indicator to show the lock was off. The other alteration was to add a bracket to hold a drip tin so that oil did not drip over the floor. Note in the background a leveling mount to cope with the floor. They also take out vibration. When I first ran the machine I could feel the vibration in the concrete floor. Now it feels much nicer. I'm hoping I can get away without having to bolt to the floor.”

Thanks Michael for that great acquisition and rebuild story.

Keep sending me email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.