This month’s story is one of acquisition by Irby Jones from Poquison Virginia, of his 15-inch Juengst & Sons.

Juengst & Sons

Front

Photo by Irby Jones

Side Showing Crank

Photo by Irby Jones

“Here is an antique shaper I won at auction, when the Tennessee Valley Authority sold some old line-shaft machines. It was part of a collection of antique machines offered to museums and non-profit organizations in late 2006. I recognized it as a Juengst & Sons shaper, probably built between 1884 and 1889. Cope's book on planers and shapers lists Juengst & Sons shapers on page 95, and says the company was formed about 1884 to build shapers with horizontal cranks.

Side

Photo by Irby Jones

In 1889, they made shapers under contract to Prentiss Tool & Supply and by 1907 put their own name on the machines. Art Volz and I studied the patent for this shaper years ago because it was among the first attempts by manufacturers to vary the ram speed during a cut and return cycle. Modern shapers generally use a pivoting yoke and slider to provide the ram speed variation.

About the same time, other manufacturers like Hewes & Philips introduced non-circular gears to get the same speed variation.

Where is the Name?

Photo by Irby Jones

It's what I thought it was!

I've been scraping away crud all over the place on that old ex-TVA shaper, trying to find a name.

Found the Name

Photo by Irby Jones

FINALLY, I found the name stamped on the front of the clapper, right where the tools can hit it! It does say exactly what Cope has in his book:

The lettering is hard to make out and harder to photograph, but it's there. You can barely make it out in the above photo, so I tried to highlight the markings. It says:

GEO. JUENGST & SONS

CROTON FALLS

N.Y.

PATENTED

SEPT. 23, 1884

Serial Number 18

Photo by Irby Jones

Now I'm really tickled! And this is the 18th shaper built by them.

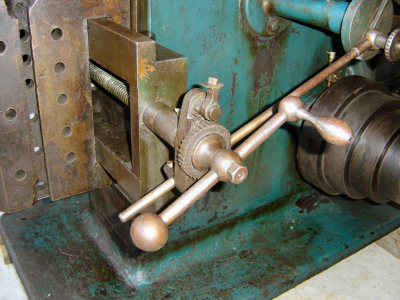

Table & Vice

Photo by Irby Jones

I've "pursued" this shaper every since I first saw it in the photos of the TVA machines back in November, 2006. There's no telling how many times I've talked to the TVA folks about it and hoped some antique machinery exhibit organization would ask for it, since it would be free to them. The bottom line is no one requested it, so it went to auction and I won.

Pawl

Photo by Irby Jones

This old shaper that's in my care now may well be very rare – only 2 others are known by me. My friend Art passed away unexpectedly last October, before this machine surfaced, but I can look at it from now on and remember the fun he and I had exploring the early shaper drive mechanisms (Art was a shaper guru). Heck, it has a 15" stroke so it's going to be very useful around my shop and will fit right in with my growing collection of 1880s & 1890s machines!

Rear Ram

Photo by Irby Jones

Patent Info

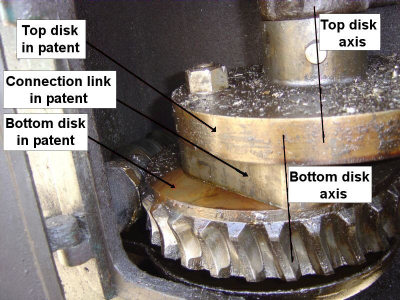

This shaper has a drive mechanism patented Sept. 23,1884 by G. Juengst, that utilizes two offset plates connected by a link to achieve a faster return stroke speed.

One Shaper to go

Photo by Irby Jones

The patent claims that this mechanism results in a rapid return motion "without the destructive and unsteady power caused from momentum of the moving parts".

Precious Load

Photo by Irby Jones

Easy Off

Photo by Irby Jones

He's probably comparing it to the conventional whitworth-type quick return that uses a long slotted arm anchored at the bottom and linked to the ram at the top. Art Volz and I found the Juengst patent a couple of years ago when we were looking at unusual shaper drive mechanisms. We couldn't find any mention of a Juengst shaper except in Cope's book on shapers and planers

Ram in Back Seat

Photo by Irby Jones

I figure my shaper is an early model, probably built after 1884, based on its earlier-looking table design and the apparent serial number of 18.

The ram stroke is adjustable up to 15" and I figure it weighs about 1600 pounds with the vise. It appears to have all the original parts.

Getting this machine has been a great adventure. It started out back in November when I recognized it and ended with me carrying it back through the Tennessee and Virginia mountains in my under-powered ½ ton Ford Ranger. It's here to stay :)

Ram out Back Seat

Photo by Irby Jones

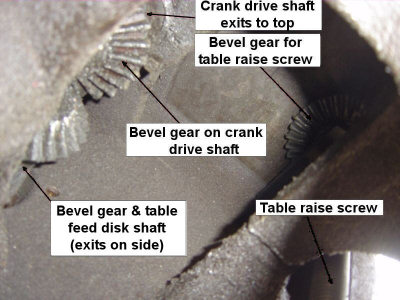

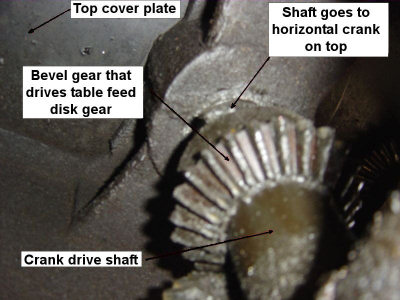

It looks like the worm drive is original (in design at least) since the housing inside is designed to hold the gearing that's there. It's a double start worm gear, but I didn't measure the pitch. The worm wheel has 27 teeth if I counted correctly.

Drive Plate

Photo by Irby Jones

The patent shows a bevel gear from the cone pulley driving a small spur gear, driving a large spur gear attached to the bottom plate. My shaper has just the worm driving the bottom plate, so it's a change since the patent design.

I noticed that the patent was applied for in Oct. 1883 and granted in Sept. 1884, so the patent drawing was done probably a year and a half before it was granted.

There's a little wear showing on the worm gears. They also look polished or even ground, which surprises me on a mid-1880s machine. I need to look it over really well, but it looks like the pulley has been rotating in the opposite direction described in the patent.

Drive Plate 2

Photo by Irby Jones

If so, that may mean the gearing isn't actually worn for the faces used in turning the correct direction. That would be nice! The bevels I can see inside look like I'd expect for 1880s.

I intend to restore this and scrape it in eventually so it cuts as true as any modern shaper - then use it all the time.

Juengst & Sons Shaper & Art Volz

It turns out our old friend Art had taken a liking to Juengst & Sons shapers a long time before I met him and he told me about them.

View from Bottom

Photo by Irby Jones

A search of the Yahoo Group Metal_Shapers message archives for "Juengst" found 2 messages Art posted about those shapers in 2002 (message 2072) and 2003 (message 6743). I only "met" Art and started corresponding with him in late 2004, just after I had bought an old Schneider & Goosmann planer. I found Art while searching for shaper & planer information - his name kept popping up everywhere!

View from Bottom 2

Photo by Irby Jones

One of the topics Art and I discussed often was unusual shaper drive mechanisms, and he liked the offset plates of the Juengst shapers. Art and I were interested in making a 3" stroke scale model from either the Juengst & Sons shaper or the Hewes & Phillips shaper. We couldn't find any mention of Juengst & Sons shapers.

In fact, after a year of us talking about building such a model, Art formed the Hewes_Phillips group to do just that.

The memory of Art's fascination with Juengst & Sons shapers was a driving force in my pursuing the one I have now. I had found 3 existing Hewes & Phillips shapers, had talked to their owners, and had photos of them, but the Juengst & Sons shapers had eluded our search. Then this one popped up at the TVA and the rest is history. Now it sits in my shop.

Just when I thought the old Juengst shaper I got was possibly the last of it's breed, I discover two more around. One is owned by Jim Mackessy in Syracuse, NY. It has a patent date of Sept. 3, 1890 stamped into the front of the clapper and is serial number 1028. Another, of the same patent date and serial number 906, is owned by a fellow on the Metal_Shapers group, Richard Krebs, in Othello, Washington.

It's a real shame Art isn't with us to see this shaper in real life.

The shafts are all loose in the housing, allowing the gears to wobble some, so I need to re-bush them eventually. The end of the cone pulley shaft has a babbit bushing where it is supported in the side of the housing. I can't tell what the rest have.”

On the next 3 pages are copies of the Juerngst patent that Irby mentioned.

Thanks Irby for that great acquisition story.

Keep sending me email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.