This month’s story is one of acquisition and rebuild. Tomas Blanchard from Napa California submitted this story about his 8-inch Boxford.

Boxford After Paint

Photo by Thomas Blanchard

“I just bought a Boxford shaper and am having a great time cleaning and polishing the bright work. I found some galling on the ram ways but 722 strokes with my diamond stone flattened out the high spots and the gib settled in so it is sliding nicely. From the history available to me, this little machine has spent most of its life in storage. I plan to make it the queen of my shop. I am considering a DC conversion to gain variable speed.

I have polished the “bright work” with a Blue 3M 1X42 polishing belt, which got the metal brighter than a charged buffing wheel, and sealed with lacquer. It is interesting that this “Made In Halifax, England” Boxford came with a lantern style tool post.

In the switch box, I found a barely discernible assembly card dated 1973 stating the machine was to go to customer “Garrett”.

Before - In Pickup

Photo by Thomas Blanchard

The switch box was covered with a single phase motor starter made in USA. It was ugly as sin, so it is removed. I developed a cover that I feel is easier to modify and flush with the cabinet.

New Motor Starter

Photo by Thomas Blanchard

Power goes from the fuse to the lighted switch on the left. When turned on, it is lit indicating line power available to the center miniature magnetic switch. Press start and the right hand light turns, on indicating power to the motor.

Before Paint

Photo by Thomas Blanchard

The Ram traveled faster on the forward motion! After reading shaper column 4 (motor direction), I changed the motor leads to correct the problem.

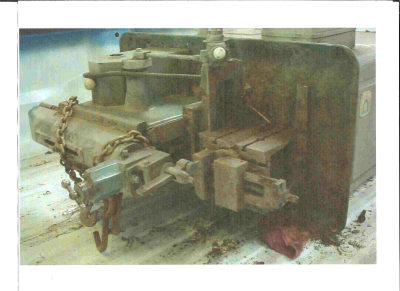

Before Paint #2

Photo by Thomas Blanchard

I bought this machine unseen after running a post on Craig's List. The first and only response came in 7 minutes. I had no knowledge of the Boxford brand but when I researched shapers at the Yahoo "Metal_Shaper" group, I found a link to a site in the UK describing Boxford shapers.

www.lathes.co.uk/shapers/index.html

After on Casters

Photo by Thomas Blanchard

I put casters on it as it must be portable in my shop.

Polished Bright Work

Photo by Thomas Blanchard

I then realized I had made a good deal. The previous owner and I had served apprenticeships out of the same local. He agreed to deliver; he wanted to see my shop! We've become chums. $300 delivered seemed more than fair.

Traverse Adjust

Photo by Thomas Blanchard

I got the paint color as close to original as possible by matching the color on the inside of a door.

The wiring of the new starter is a story of not counting on the supplier to have any knowledge of their product. I plan to add limit switches as mentioned in shaper column 55.

This Shaper, serial number 70154, finished manufacturing in May 1975, and was sent to Brodhead Garret Company.

Time for this machine to go to work.

New Paint

Photo by Thomas Blanchard

I plan to replace the cheap plastic knobs with some that I will make; however I need to make a radius tool holder first. I also plan to fabricate some special tool holders, either copying or very similar to those by Rudy Kouhoupt.”

After Pulley Cover

Photo by Thomas Blanchard

Thank you Thomas for that interesting story.

Keep sending me email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.