This month’s contribution comes from fellow NEMES member and friend Bob Neidorff. I asked Bob if he would create a safe schematic for adding limit switches to a shaper. Coincidently I was as a very good stage in rebuilding my Logan shaper to implement his plans. The following is from Bob:

“Here's electrical advice on safely adding limit switches to your shaper or any other power tool. I'll leave it to your ingenuity to determine how to mount the limit switches.

To safely deal with the power line, you must isolate the human from the power line so that there is no risk of electrocution. We'll use two common devices for this: a relay and a power transformer.

For this job, there are two practical types of relays. One is a mechanical relay (also called a contactor). The other is a solid state relay. These both behave the same way. When power is applied to either relay, the relay will turn on and complete the circuit from the power line to the motor.

Solid state relays have a few advantages. They are small, quiet, don't wear out, and can be controlled by low voltage, low current signals. Note that the input to a solid state relay has a positive and a negative terminal and must be wired correctly. Mechanical relays also have advantages. They can take occasional abuse without failing and they are available in multiple pole varieties.

Grainger is a good source for relays. One good candidate solid state relay is Figure 1, Grainger #6C903; Omron G3NA-225B-DC5-24; $21.42. This relay turns on with any input between 4V and 32VDC, consumes under 7mA, works with any output current between 0.1A and 25A and any voltage between 19VAC and 264 VAC. This relay is adequate for any motor up to 3 HP.

www.grainger.com/Grainger/wwg/itemDetailsRender.shtml?xi=xi&ItemId=1611785082

Figure 1: Omron G3NA-225B-DC5-24 Solid State Relay

Grainger also has mechanical relays. For example, Figure 2 Grainger #4JY24 Dayton # B101HXX-12D; $64.00. This relay is a very high current relay that has a coil rating of 12VDC at 800mA and a contact rating of 100A @240 VAC resistive or inductive so it is good for any motor up to 5HP. www.grainger.com/Grainger/wwg/itemDetailsRender.shtml?xi=xi&ItemId=1613549071

Figure 2: Dayton B101HXX-12D Mechanical Relay

A smaller mechanical relay from Grainger is Figure 3 #5Z550; Dayton #5Z550; $13.84. This relay has a coil rating of 12VDC at 200mA and is rated for motors up to 2 HP www.grainger.com/Grainger/wwg/itemDetailsRender.shtml?ItemKey=5Z550

Figure 3: Dayton 5Z550 Mechanical Relay

The easiest way to get the advantages of a power transformer is to use an old A C adapter (Figure 4) that puts out between 6V and 12V DC at 100mA or more. Some people call these "wall warts" because they look like an ugly bump on the wall. There’s no need to modify it or disassemble it. It already contains the circuits required to turn high-voltage AC into safe low-voltage DC. Make sure that the power adapter output rating is appropriate for the input rating of the relay that you select. For example, the very high power 4JY24 mechanical relay has a coil that requires between 10VDC and 12VDC at 800mA but the Omron solid state relay needs between 4VDC and 32VDC at 7mA.

Figure 4: Typical AC Adapter (wall wart)

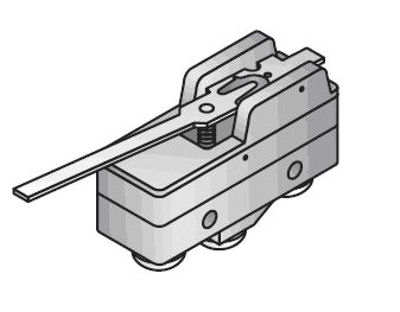

For limit switches, you need SPDT mechanical switches. These come in many different sizes, shapes, and mounting configurations. Industrial roller limit switches (Figure 5) are a good choice. They are rugged, easy to mount, and have a very well controlled trip position. Another good choice is leaf spring micro switches (Figure 6). The spring-steel leaf can be bent to adjust the switch operating point and will also flex to prevent damage if the machine travels too far. You can even use the micro switch found in a computer mouse or the interlock switch (Figure 7) from surplus machinery. If the switch is double-throw, it can be adapted to the job.

Figure 5: Typical Industrial Roller Limit Switch

Figure 6: Low Cost Leaf Spring “Micro Switch”

Figure 7: Two Different Types of Interlock Switches

There are also other ways to sense table position, such as proximity switches and optical switches. These sensors are most commonly used with computer controlled equipment where a low-level logic signal from the sensor is fed to a low-voltage controller (PLC or computer). Optical and proximity switches can be extremely small and sensitive, but for shaper or other power tool use, mechanical switches are preferred.

Figure 8: Schematic Diagram of Motor Control with Limit Switches

This diagram shows the AC Power Adapter as a transformer, diode, and capacitor. All of these parts are built into the power adapter, so you don’t need to select or wire these individual components.

In this circuit, the “Start” button is a momentary-action pushbutton switch that must be normally open and rated for power line voltage. The “Stop” button is also a momentary-action pushbutton switch that must be SPDT. The “Stop” button can be a high voltage or low voltage switch.

The 10 ohm resistor discharges the capacitor in the AC adapter quickly when the off or limit switch is pressed. A ½ watt or larger resistor will work for this purpose.

Good motors are expensive. I strongly recommend putting a fuse on each side of the power line to protect the motor from a stall condition. A low cost fuse may also save your shop from a fire.

When the table pushes on one of the limit switches, power will be removed from the motor so the motor will coast and eventually stop. Depending on the load on the motor and the inertia of the motor, the motor might continue to rotate for a few more revolutions or a few hundred more revolutions. This means that the table will continue to move some distance past the point where the limit switch is activated.

The limit switch must be installed in such a way that it will not be damaged if the table passes the switching point. For example, roller limit switches can be installed so that the table rolls past the switch rather than pressing right into it. Also consider the shaper and the work itself to make sure that the table still has some room to travel past the limit switch.

When installing limit switches on a lathe or a mill, the same considerations apply. In some cases, the table or tool is driven by a different motor than the spindle. In these cases, the limit switch can stop the table or tool travel but the spindle could remain powered.

In most cases, the limit switch will be placed a short distance past the edge of the work, so that the motor stops with the tool off the work. Other times, you want to stop a cut with the tool in the work, for example, to create a shoulder. Repeatedly stopping a cut at exactly the same point in the work will build up a wall of burrs. This wall will grow higher and wider with each pass, so each successive pass will put higher stresses on the tool. On a mill, this won’t be a problem because the cutter will remove the burr from the face of the cut. However, this is a real problem on the lathe, and is normally solved by cutting a relief groove at the end of the cut or by moving the limit switch a small distance closer into the work after each pass. A similar approach may be beneficial on the shaper.”

Thanks Bob for that great and very useful schematic. But the thanks has to go even further. After several email exchanges, Bob sent me an electronics care package with a hard to find dual pole dual throw spring loaded start stop switch and some limit switches.

Electronics Kit

Photo by Kay Fisher

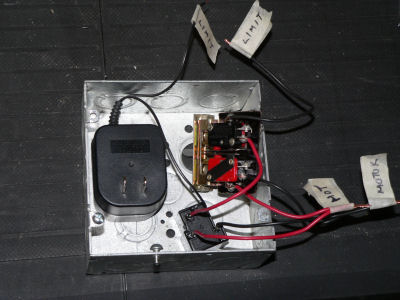

My next-door neighbor gave me a circuit box of just the right size and a AC adapter. I found a relay at Fry’s Electronics for $5.00.

Parts in Box

Photo by Kay Fisher

Above was the proposed layout of the wart, switch (which also acts as the mount for the whole arrangement) and relay.

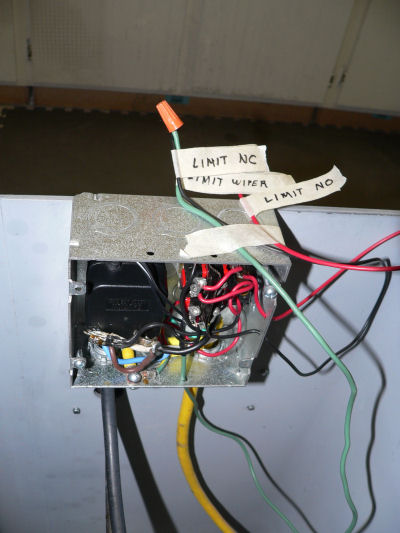

Wired and Ready for Test

Photo by Kay Fisher

Testing the circuit the first time failed because of a wiring error on my part. Testing the second time failed because of the capacitance of the wart which lead to a change in the schematic which added the 10 ohm bleeder resistor.

Switch Mounted Incorrectly

Photo by Kay Fisher

Above you see a picture of the switch box mounted unfortunately in the wrong hole in the front of the shaper. This hole is for the vertical crank and the unused hole to the right is where I should have mounted it. But it worked

Adding Insulation

Photo by Kay Fisher

After several coats of liquid electrical tape and a plastic spacer to hold the transformer securely I thought I was ready to button it up.

Box Mounted Correctly

Photo by Kay Fisher

Above, I moved the electrical box to the correct position.

Extra Holes!

Photo by Kay Fisher

Now I just have to fix those holes I drilled (and elongated) for the switch plate and the power switch.

Bondo Mistakes

Photo by Kay Fisher

A little Bondo, sanding, spotting putty, sanding, primer, more spotting, sanding, primer and paint and the old hole looks as good as new.

Front Finished

Photo by Kay Fisher

Now the shaper has the limit switch circuit installed and waiting for the rest of my rebuild before I get to mount the micro switches in the knee.

Thanks Bob for the great info on safely installing limit switches.

Keep sending me email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.