Art Volz in Houston Texas has been collecting unique Shaper things for some time. This is his story of acquiring a rare shaper and matching vise.

“In October 1999, my neighbors across the street went on vacation to Rome. They asked me to pick up and dispose of their daily Houston Chronicle newspaper. I agreed. I don't read the Chronicle - I have problems accepting their "factual" writings. Every now and then, though, I'll buy a Friday morning edition and scan the classified ads for "machinery". The first Friday that they were gone, I picked up their paper and instead of immediately tossing it into the trash I looked under "machinery".

Eureka! A 10-inch metal shaper was being offered at $240 along with a huge odd-ball vertical mill. I called. The seller said that another guy was coming from the other side of Houston to buy it at noon. I said that I would call him at one o'clock to see what had transpired. At one I called again. The other guy hadn't arrived yet, but had called and said he would be late.

I asked the seller whether he still had the mill, to which he replied that he did, and I then arranged to see it at 3 PM. When I arrived, the supposed buyer of the shaper hadn't arrived yet and hadn't called again. I looked over the mill. It was a gargantuan (HEAVY) obscure vertical of the WWII era. I decided that it would be best if it were melted down to make iron for new machines.

I turned my attention to the shaper sitting on an angle iron stand in the rear of the garage shop. I couldn't believe my eyes: It was a Lewis.

Lewis 10" Shaper

photo by Art Volz

It looked to be one of those kits that had been purchased by a vocational school, machined and assembled by the students, and then retained in the school shop. I quickly convinced the seller, a retired South African engineer, that my $240 in his hand was better than the money from the other guy who still hadn't arrived. As we talked--and I disassembled the Lewis into easily handled segments transportable in the rear of my van (a Quest, what else?) the seller asked "Did I give you the tool holder yet?" Out of the goodness of his heart, he then gave me an original Atlas adjustable tool holder. I exclaimed (this was during my pre-internet days): "These can't be found anywhere! Thanks!" I asked him about the shaper’s vise. He said that the vise had already disappeared when he got the shaper.

Time passed. In the spring of 2000, I finally got on the internet. One of my first finds was the Chaski metalworking group:

www.chaski.com/wwwboard/index.html

In March, a member from Detroit, Ron B., advertised a Logan/Montgomery Ward 10 x 24 lathe for sale at a reasonable price. I struck immediately, sent a down payment, and agreed to pick it up the weekend before NAMES 2000 in Detroit as I would be both visiting family in Lansing and intended to attend NAMES. I love that lathe! And I really needed one since my c. 1890 motorized velocipede Barnes 4-1/2 had lost its Babbitt spindle bearings in a fire in my shop fire 5 years ago.

While at NAMES 2000 and 2001, I searched every vendors’ table. No one had a Lewis vise or knew of one being offered for sale. I kept my nose to the ground and my gum-shoes moving. I scoured the internet for leads and religiously scanned eBay offerings on a daily basis. Nothing. I did find a Lewis horizontal milling machine vise on eBay along with a Lewis mill. The mill vice is exactly one-half the scale of the shaper vise, with 3½ inch wide jaws compared to 7-inch wide jaws. But the seller wouldn't sell that vise separately. (I still NEED a Lewis 3½ inch vise for my Lewis mill - the one Burton built.) While at NAMES 2001, I spoke with Rich C. (the "Green Bay Steamer") at his table with the Chicago Model Club and I had a notebook, with pictures of the Lewis shaper, open on the table. A voice to my right exclaimed "I built one of those - back in the 40's." The 80-ish year old gent told me how he had machined a Lewis shaper from a kit of parts and that his son now had it. I asked him if he still had the blueprints for the vise. He did! Several months later he sent me dimensioned drawings of the Lewis vise.

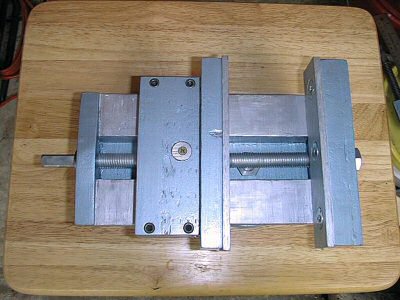

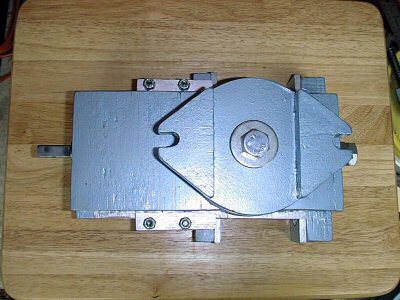

That winter, still not getting any leads on an actual Lewis vise, I made a mock-up/working-model of the Lewis vise from the prints. I modified some of the parameters for simplification and ease of machining with the intent of making a set of patterns and having raw castings made in ductile iron.

Model Lewis Vise (Top)

photo by Art Volz

Model Lewis Vise (Bottom)

photo by Art Volz

However, I couldn’t find a local foundry that would do quality one-offs at a reasonable price. I did send my model to both Marty E. (Phoenix) and Rich C. (Green Bay) for review and comment, but never went back and made the patterns. I just kept looking...and looking...and looking.

I was unable to attend NAMES 2002, although I was in the Lansing area, but corresponded with Mario V. (St. Lewis/Detroit) who would be there. I got Mario to attend the "reception" that Scott always has on the Friday evening before NAMES, where he met and had suds with Peter V. (Sudbury). When Joe Mama finally acquired a Lewis shaper in October 2002, he posted a set of pictures of it at our site. An original Lewis shaper vice came with Joe's shaper. At the time, I remarked that if Joe didn't want the vise, I'd immediately buy it from him, but he refused. A few days later I received email from Peter V. with a set of three pictures of a vise he had seen at NAMES that year.

Lewis Vise

photo by Art Volz

He didn't know it was a Lewis vise when he took the pictures, but knew that it was a shaper vise. He considered buying it at the time, but was unsure whether it would fit his Alba. Seeing Joe's vise and now knowing that I was looking for a Lewis vise for my shaper, Pete sent me email saying that he had seen the pictured vise at NAMES and that it had been offered for sale by Ron B from Detroit. Pete offered to contact him if I wanted the vise.

Small world! Ron B sold me my Logan lathe. I told Pete that I knew Ron and would try to get in touch with him. His old email addresses bounced so I wrote Ron a letter. The post office returned it to me as he had moved, but the USPS had, fortuitously for me, printed his NEW address on the yellow return label.

Time passed. Other projects/activities demanded my attention. At Thanksgiving, Mario remarked that he had missed a Lewis vise at one time. Mario has a Lewis shaper too. I responded that he had missed TWO Lewis vises. I told him of the one that he didn't "see" at NAMES. To make a long story a bit shorter, Mario offered to deal with Ron B. for me and was able to purchase that Lewis vise. I had him take it home to "try out" on his Lewis. I received that vise yesterday from Mario.

Lewis Vise (Top)

photo by Art Volz

Lewis Vise (Bottom)

photo by Art Volz

It is now sitting on my kitchen table next to my painted model. They're kissing twins.

Interestingly, there is a round-cornered rectangular lozenge-shaped boss on top of the rear jaw. It is stamped "D MAGILL". In the old days, machine shop students often made useful tools which they took with them and used thru out their lives. I still have a 1"- 2" micrometer that I machined in 1960 while taking the required machine shop course in engineering at Notre Dame. It is one of my prized possessions.

Art Volz Micrometer

photo by Art Volz

In 1942, a set of Lewis shaper vise castings and prints were only $4.75 with quoted freight per CWT to Detroit at $3.21. The vise kit's shipping weight at 40 lbs would cost about $1.30 for a total student cost of about $6.10. Not cheap for 1942, but affordable and a super student project. The vise that D. Magill made is virtually a virgin - only one "trial" errant "learning" cut can be seen on the top of the jaws. Magill apparently ran out of time, as the jaw plates are still in the process of final machining. I wonder where this vise had been for the first 60 years of its life.

The vise that Mario sent to me has jaws 7-inches wide and a depth of 1½ inches. The jaws open 4¼ inches and the vise stands 4½ inches tall. The most amazing spec, however, is its weight: only 27 lbs as weighed on my bathroom scale. I had expected it to weigh close to 40 lbs as my copy of the 1942 Lewis catalog listed the shipping weight of the vise kit at 40 lbs. 27 Lbs is sweet! The 6-inch shaper-style vise that I received last week (the Chicago made vise (eBay) from J.E. Plunket who also made small IC farm duty engines around 1909) weighed 41 lbs. Compare this light weight Lewis vise to a typical Kurt clone 6-inch milling machine vise at about 100 lbs. Generally speaking, shaper style vises are quite a bit lighter than the same jaw size milling machine vises.

So there you have it: a story of a quest completed and a quest continuing. Does anyone know of a Lewis 3½ inch milling machine vise for sale? It looks exactly like the pictures of my Lewis shaper vise at our site (photos from Pete V.) (See the Lewis Vise Album)

Thanks Mario! Thanks Pete! Thanks Ron! Thanks Rich! Thanks Marty! Thanks to all!

Art, elated in Houston North on a cold winter day.”

Thanks Art for that wonderful acquisition story.

Keep sending me email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.