This page shows some tooling that I made for my Atlas 7B shaper: a toolholder with an internal cutting arbor and a "stubby" toolpost. The ideas for the toolholder and arbor came from drawings made by Art Volz that are posted on the web at the Yahoo Metal_Shapers group (http://groups.yahoo.com/group/Metal_Shapers). The drawings are in the Files section (membership required) as holder1.jpg and holder2.jpg, and also available at www.kinzers.com/don/MachineTools/shaper_toolholder/holder1.jpg and www.kinzers.com/don/MachineTools/shaper_toolholder/holder2.jpg.

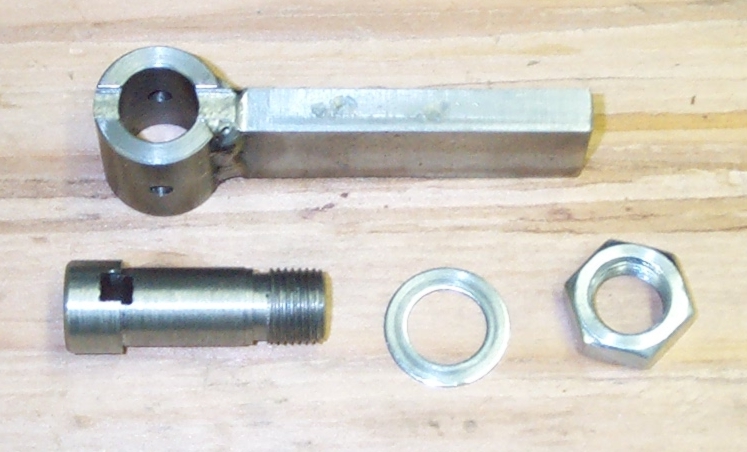

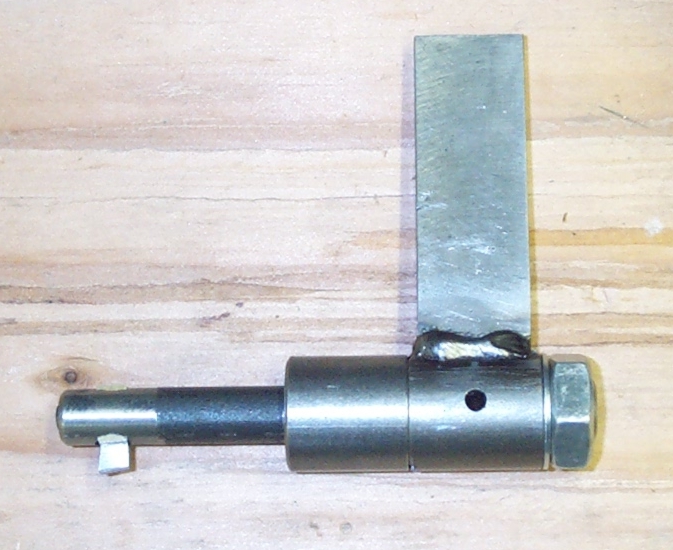

This is the basic toolholder. The shank is made from 3/8" x 1" bar stock about 3.5" long. Welded on the end of the shank is a cylinder made from 1" round stock bored for a 5/8" shaft. After welding, a slot was milled across the top to accept a 1/4" HSS bit. The bit clamp (see second picture) is made from 3/4" round stock turned down to 5/8" over most of its length with 5/8-18 threads cut on one end to accommodate a jam nut. The square hole for the 1/4" HSS bit was made by first drilling a 17/64" hole and then forcing a crude 1/4" square broach (see the third picture) through the hole using an arbor press. A little dressing with a small file opened the roughly square hole enough for a 1/4" square bit to be easily inserted. The broach was made using a 1/4" square HSS bit ground roughly round with some cutting edges at the corners.

Toolholder Parts Photo by Don Kinzer

Crude Broach Photo by Don Kinzer

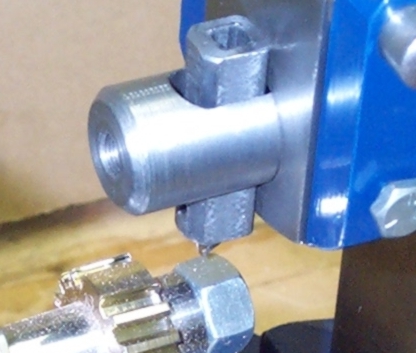

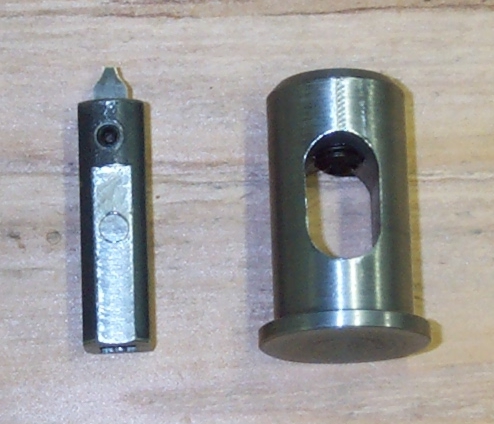

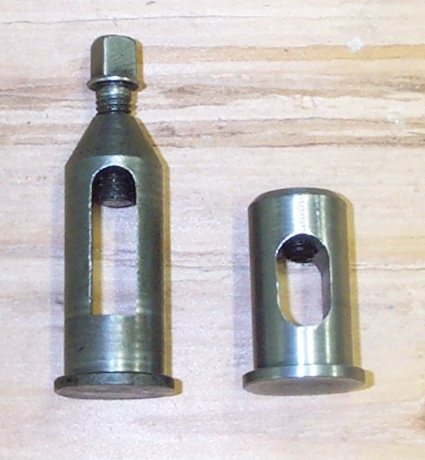

For internal cutting, e.g. splines, keyways, etc., a slim arbor is added to the basic toolholder. The bit shown in the arbor was ground for cutting square internal splines in a gear (a web page about that process can be found at www.kinzers.com/don/MachineTools/internal_spline/). The arbor itself is made from a short length of 1" round stock turned down to 5/8" and threaded for the jam nut. The arbor extension is made from 1/2" round stock which is pressed into the end of the 1" arbor body. A hole is drilled and tapped in the end of the arbor extension to lock the bit into place in a square hole made using the same broach as above. The hole drilled through the barrel of the toolholder is sized for a 1/8" roll pin which helps keep the arbor from rotating.

Internal Cutter Parts Photo by Don Kinzer

Lastly, for a gear cutting project (see the web page www.kinzers.com/don/MachineTools/gear_cutting/), I needed a toolpost that was shorter than the standard Atlas toolpost to avoid hitting other parts of the setup. That need gave rise to the "stubby" toolpost seen here. The body of the toolpost was turned from 1-1/4" round stock. The main body diameter is 0.995" and the 0.125" flange is about 1.125" diameter. These dimensions fit the clapper of the Atlas shaper. The slot in the toolpost was cut with a 1/2" endmill and the end of the toolpost is drilled and tapped for a 3/8-16 set screw. The toolholder is made from 3/4" round stock with a 1/4" square hole broached through it and then milled flat on three sides to fit the slot. A 10-32x3/16 setscrew holds the bit in place. The third picture shows the relative sizes of the standard and stubby toolposts.

Toolpost and Spine Cutter Photo by Don Kinzer

Toolpost Comparison Photo by Don Kinzer

Thanks Don for that great article and photos.

Keep sending email with questions and interesting shaper stories.

My email address is KayPatFisher@gmail.com.